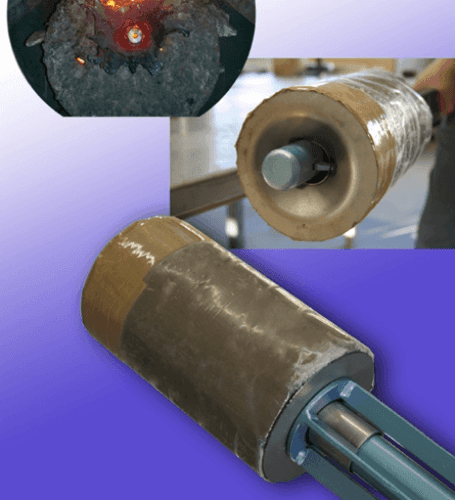

Dart setting machinery and FLOWDART object are used for slaglimiting of the rest top slag during tapping. Dart and Coneplast Stopper cut off 90 % of the total possible slag transfer

ConePlast

converter flush slag stopper

- FlowDart converter slag stopper

FlowGuard tundish antisplash box

- Deflux tundish antivortex system

Welcome to SMTS Stilkerieg GmbH

Your specialist

for slaglimiting in Converter and Tundish

SMTS Stilkerieg GmbH was founded from Dipl.-Ing. Veronica Stilkerieg in 1997 as the owner of the worldwide

CONEPLAST Stopper Patents.

In the past the Stilkerieg GmbH had given the license in know how and rights for manufacture and sales to different companies in China, India,Turkey, USAToday we manufacture in the Eifel area with two manufacture lines and capacity of 15.000 stoppers/month stoppers from 65mm diameter up to 180 mm and in a new cooporation in Bottrop-Kirchhellen with KBO GmbH ( Ruhr area) 6.000 stoppers/month with new materials for bigger stoppers up to 280mm diameter for tap hole diameter >300 mm with the same knowhow and technique.

We have a best trained team in manufacture, service and customer care.

Our philosophy is to offer our customers best quality for the best possible price.

Our philosophy is to offer our customers best quality for the best possible price.

Development of our materials in our products are for us the market order and all new knowledge will lead direct to our customers.

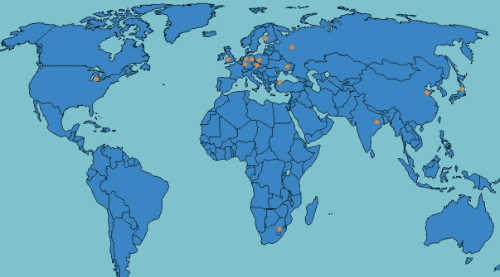

We are serving now customers in 15 countries worldwide all together with agencies, representatives and our own personally team.

We all look for a good cooperation with our customers and try to fulfill customers requirements.

We are serving now customers in 15 countries worldwide all together with agencies, representatives and our own personally team.

We all look for a good cooperation with our customers and try to fulfill customers requirements.

Our representatives and sales offices worldwide

CONEPLAST flush slag stopper

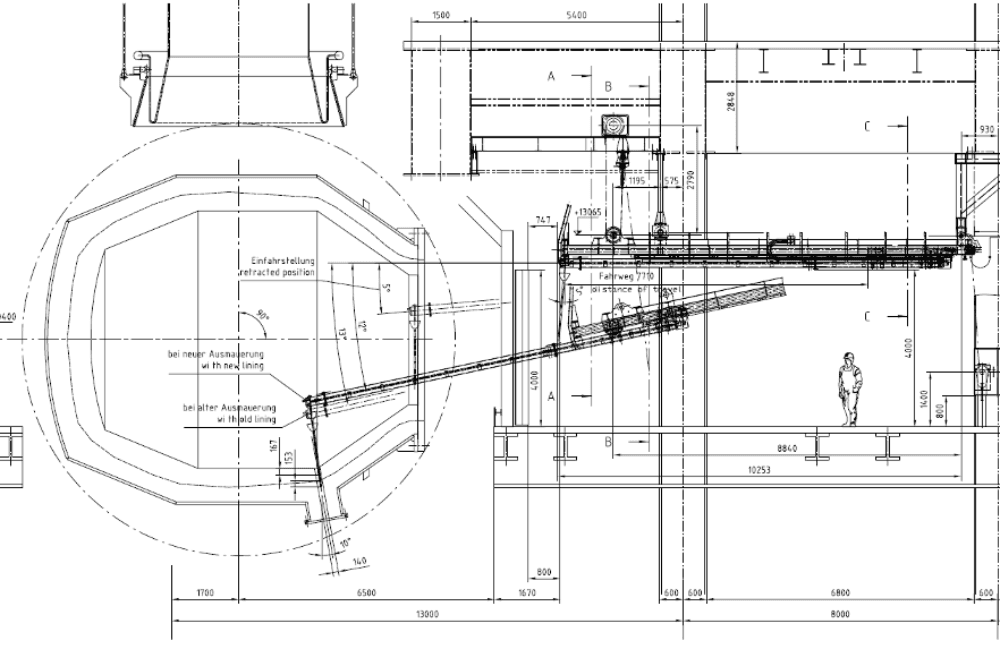

Slag limiting system for tiltable converter

Cutting off the flush slag, reduction of the

transferred slag during tapping

Prevention against starting vortexReduction in the use of aluminium

and alloy materials

Lower slag amount means

constant steel quality

lower amount of oxygen

Cleaner ladle lid

Longer life of the ladle wall

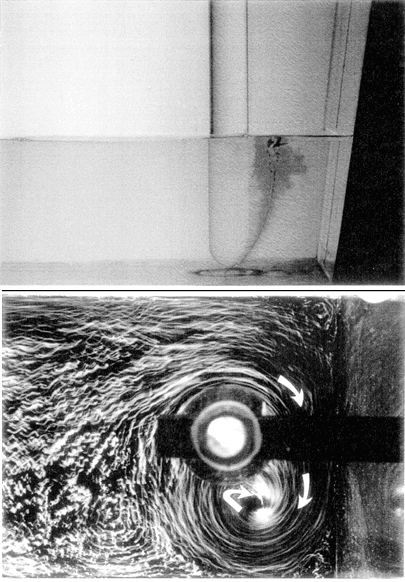

DEFLUX anti - vortex systemfor tundish

During continuous casting process liquid steel is transferred from the tundish into the mould. The casting speed is regulated by stoppers, sliding gates etc. At the end of the sequence and during ladle changes within the sequence the risk is high that vortex occoured which transfer slag from the steel surface into the mould. This will lead to inclusions within the strand. The DEFLUX system helps to stop those vortex.

FLOWDART

converter slag limiting for top-slag